Industrial IoT

Multiple sensors and devices, one solution provider

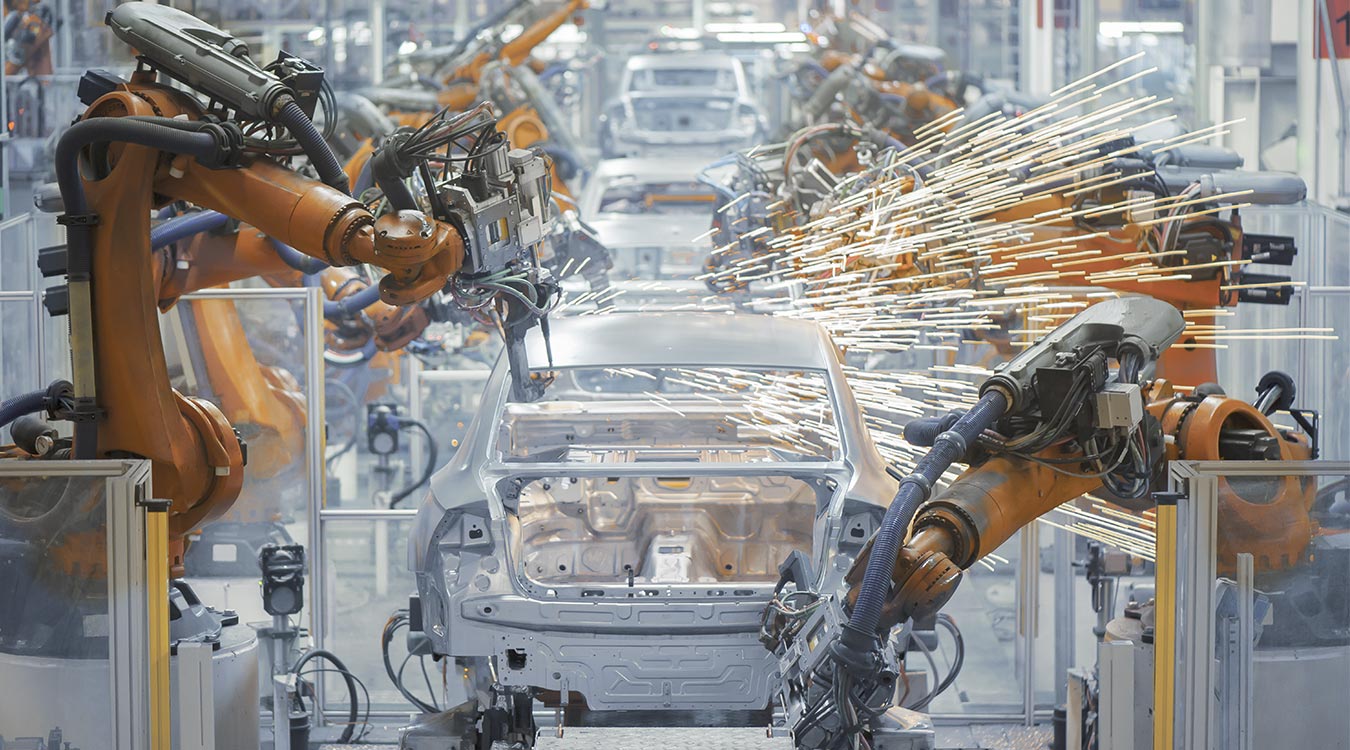

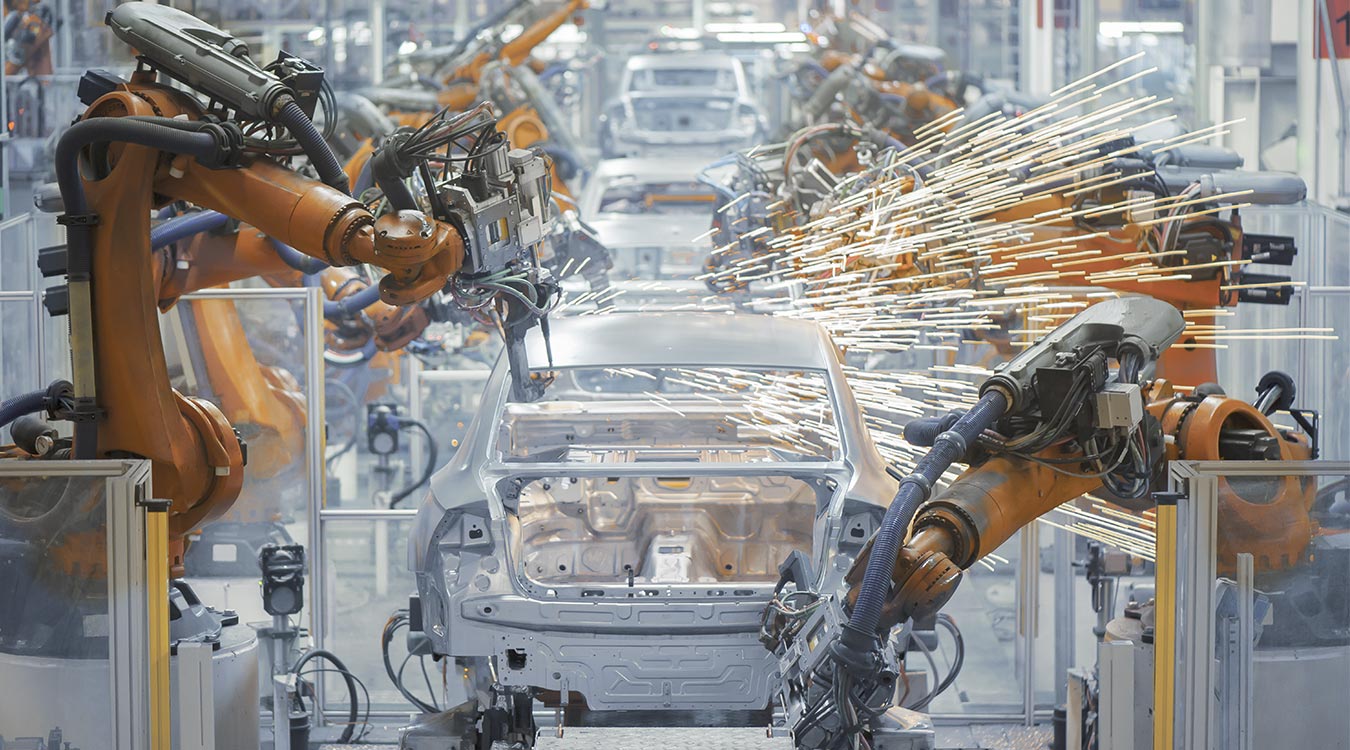

Long cabling distances, bandwidth limitations from legacy connectivity systems, complex multi-protocol management: these are some of the intricate connectivity challenges posed by the increasing density of sensors, actuators and controllers in smart factories.

Long cabling distances, bandwidth limitations from legacy connectivity systems, complex multi-protocol management: these are some of the intricate connectivity challenges posed by the increasing density of sensors, actuators and controllers in smart factories.

Long cabling distances, bandwidth limitations from legacy connectivity systems, complex multi-protocol management: these are some of the intricate connectivity challenges posed by the increasing density of sensors, actuators and controllers in smart factories.

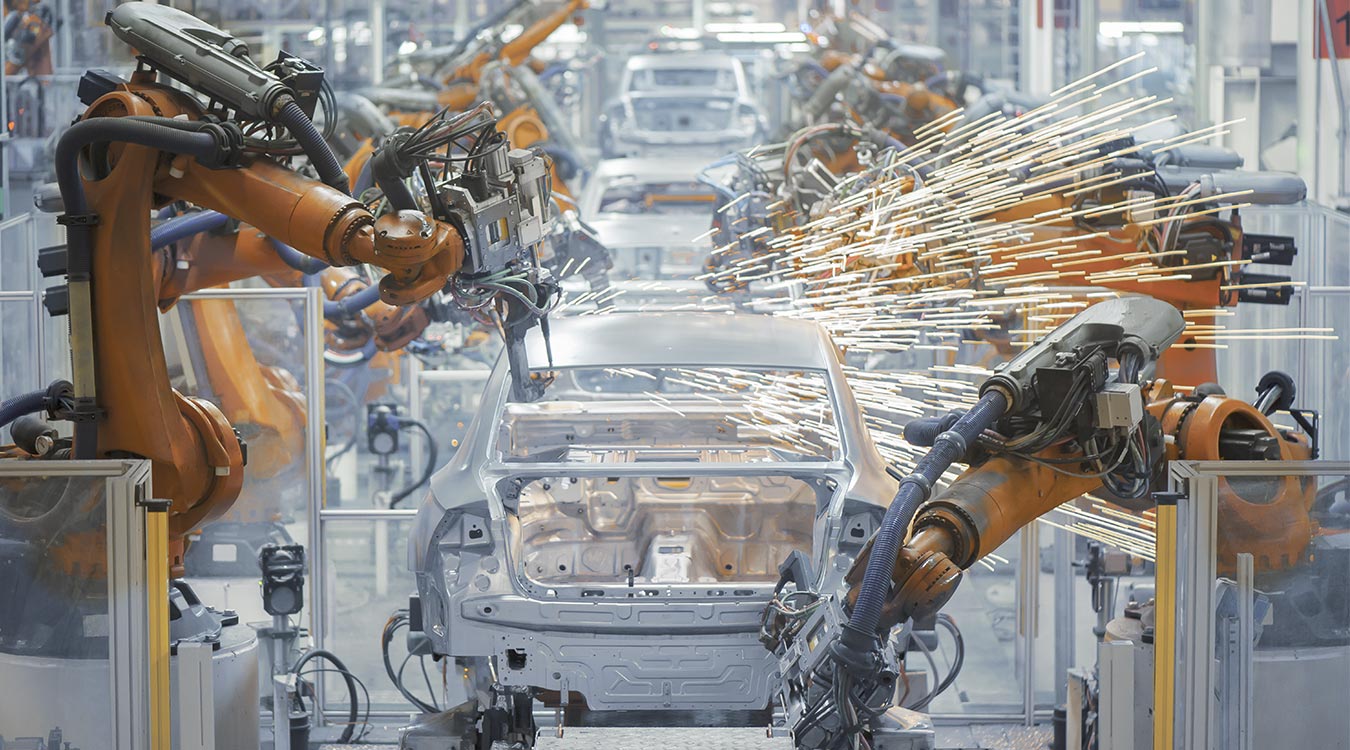

Harsh operating conditions add another difficulty level. Equipment, devices and robots are exposed to chemicals, vibration and extreme temperatures which can directly impact the functioning of IoT ecosystems’ communication platforms.

To work out this connectivity equation and support customers’ digital transformation, our solutions come in handy. Our offer ranges from high-performance data transmission solutions, such as fiber optic and Single Pair Ethernet, to full electronic ecosystems integrating miniaturized devices.

Harsh operating conditions add another difficulty level. Equipment, devices and robots are exposed to chemicals, vibration and extreme temperatures which can directly impact the functioning of IoT ecosystems’ communication platforms.

To work out this connectivity equation and support customers’ digital transformation, our solutions come in handy. Our offer ranges from high-performance data transmission solutions, such as fiber optic and Single Pair Ethernet, to full electronic ecosystems integrating miniaturized devices.

Harsh operating conditions add another difficulty level. Equipment, devices and robots are exposed to chemicals, vibration and extreme temperatures which can directly impact the functioning of IoT ecosystems’ communication platforms.

To work out this connectivity equation and support customers’ digital transformation, our solutions come in handy. Our offer ranges from high-performance data transmission solutions, such as fiber optic and Single Pair Ethernet, to full electronic ecosystems integrating miniaturized devices.

Long cabling distances, bandwidth limitations from legacy connectivity systems, complex multi-protocol management: these are some of the intricate connectivity challenges posed by the increasing density of sensors, actuators and controllers in smart factories.

Long cabling distances, bandwidth limitations from legacy connectivity systems, complex multi-protocol management: these are some of the intricate connectivity challenges posed by the increasing density of sensors, actuators and controllers in smart factories.

Long cabling distances, bandwidth limitations from legacy connectivity systems, complex multi-protocol management: these are some of the intricate connectivity challenges posed by the increasing density of sensors, actuators and controllers in smart factories.

Harsh operating conditions add another difficulty level. Equipment, devices and robots are exposed to chemicals, vibration and extreme temperatures which can directly impact the functioning of IoT ecosystems’ communication platforms.

To work out this connectivity equation and support customers’ digital transformation, our solutions come in handy. Our offer ranges from high-performance data transmission solutions, such as fiber optic and Single Pair Ethernet, to full electronic ecosystems integrating miniaturized devices.

Harsh operating conditions add another difficulty level. Equipment, devices and robots are exposed to chemicals, vibration and extreme temperatures which can directly impact the functioning of IoT ecosystems’ communication platforms.

To work out this connectivity equation and support customers’ digital transformation, our solutions come in handy. Our offer ranges from high-performance data transmission solutions, such as fiber optic and Single Pair Ethernet, to full electronic ecosystems integrating miniaturized devices.

Harsh operating conditions add another difficulty level. Equipment, devices and robots are exposed to chemicals, vibration and extreme temperatures which can directly impact the functioning of IoT ecosystems’ communication platforms.

To work out this connectivity equation and support customers’ digital transformation, our solutions come in handy. Our offer ranges from high-performance data transmission solutions, such as fiber optic and Single Pair Ethernet, to full electronic ecosystems integrating miniaturized devices.

Long cabling distances, bandwidth limitations from legacy connectivity systems, complex multi-protocol management: these are some of the intricate connectivity challenges posed by the increasing density of sensors, actuators and controllers in smart factories.

Long cabling distances, bandwidth limitations from legacy connectivity systems, complex multi-protocol management: these are some of the intricate connectivity challenges posed by the increasing density of sensors, actuators and controllers in smart factories.

Long cabling distances, bandwidth limitations from legacy connectivity systems, complex multi-protocol management: these are some of the intricate connectivity challenges posed by the increasing density of sensors, actuators and controllers in smart factories.

Harsh operating conditions add another difficulty level. Equipment, devices and robots are exposed to chemicals, vibration and extreme temperatures which can directly impact the functioning of IoT ecosystems’ communication platforms.

To work out this connectivity equation and support customers’ digital transformation, our solutions come in handy. Our offer ranges from high-performance data transmission solutions, such as fiber optic and Single Pair Ethernet, to full electronic ecosystems integrating miniaturized devices.

Harsh operating conditions add another difficulty level. Equipment, devices and robots are exposed to chemicals, vibration and extreme temperatures which can directly impact the functioning of IoT ecosystems’ communication platforms.

To work out this connectivity equation and support customers’ digital transformation, our solutions come in handy. Our offer ranges from high-performance data transmission solutions, such as fiber optic and Single Pair Ethernet, to full electronic ecosystems integrating miniaturized devices.

Harsh operating conditions add another difficulty level. Equipment, devices and robots are exposed to chemicals, vibration and extreme temperatures which can directly impact the functioning of IoT ecosystems’ communication platforms.

To work out this connectivity equation and support customers’ digital transformation, our solutions come in handy. Our offer ranges from high-performance data transmission solutions, such as fiber optic and Single Pair Ethernet, to full electronic ecosystems integrating miniaturized devices.

Requirements & challenges

Interconnect solutions for multiple source sensors and data management

- High data speeds and multi-protocol management including Single Pair Ethernet

- Size, weight and power (SWaP) optimization for compact devices in space-constrained areas

- Maximized functionality with high density and hybrid signal & power options

Interconnect solutions for multiple source sensors and data management

- High data speeds and multi-protocol management including Single Pair Ethernet

- Size, weight and power (SWaP) optimization for compact devices in space-constrained areas

- Maximized functionality with high density and hybrid signal & power options

Interconnect solutions for multiple source sensors and data management

- High data speeds and multi-protocol management including Single Pair Ethernet

- Size, weight and power (SWaP) optimization for compact devices in space-constrained areas

- Maximized functionality with high density and hybrid signal & power options

Resistance to harsh conditions

- High corrosion resistance with up to 1,000 hours of salt mist

- Easy cleaning and maintenance with IP68/IP69 sealing (even unmated)

- Operations in vacuum or pressurized environments with hermetic solutions

- Signal integrity with excellent 360° EMC shielding

- Long life cycles with durable materials and mechanical designs resisting up to 10,000 mating cycles

Resistance to harsh conditions

- High corrosion resistance with up to 1,000 hours of salt mist

- Easy cleaning and maintenance with IP68/IP69 sealing (even unmated)

- Operations in vacuum or pressurized environments with hermetic solutions

- Signal integrity with excellent 360° EMC shielding

- Long life cycles with durable materials and mechanical designs resisting up to 10,000 mating cycles

Resistance to harsh conditions

- High corrosion resistance with up to 1,000 hours of salt mist

- Easy cleaning and maintenance with IP68/IP69 sealing (even unmated)

- Operations in vacuum or pressurized environments with hermetic solutions

- Signal integrity with excellent 360° EMC shielding

- Long life cycles with durable materials and mechanical designs resisting up to 10,000 mating cycles

Requirements & challenges

Interconnect solutions for multiple source sensors and data management

- High data speeds and multi-protocol management including Single Pair Ethernet

- Size, weight and power (SWaP) optimization for compact devices in space-constrained areas

- Maximized functionality with high density and hybrid signal & power options

Interconnect solutions for multiple source sensors and data management

- High data speeds and multi-protocol management including Single Pair Ethernet

- Size, weight and power (SWaP) optimization for compact devices in space-constrained areas

- Maximized functionality with high density and hybrid signal & power options

Interconnect solutions for multiple source sensors and data management

- High data speeds and multi-protocol management including Single Pair Ethernet

- Size, weight and power (SWaP) optimization for compact devices in space-constrained areas

- Maximized functionality with high density and hybrid signal & power options

Resistance to harsh conditions

- High corrosion resistance with up to 1,000 hours of salt mist

- Easy cleaning and maintenance with IP68/IP69 sealing (even unmated)

- Operations in vacuum or pressurized environments with hermetic solutions

- Signal integrity with excellent 360° EMC shielding

- Long life cycles with durable materials and mechanical designs resisting up to 10,000 mating cycles

Resistance to harsh conditions

- High corrosion resistance with up to 1,000 hours of salt mist

- Easy cleaning and maintenance with IP68/IP69 sealing (even unmated)

- Operations in vacuum or pressurized environments with hermetic solutions

- Signal integrity with excellent 360° EMC shielding

- Long life cycles with durable materials and mechanical designs resisting up to 10,000 mating cycles

Resistance to harsh conditions

- High corrosion resistance with up to 1,000 hours of salt mist

- Easy cleaning and maintenance with IP68/IP69 sealing (even unmated)

- Operations in vacuum or pressurized environments with hermetic solutions

- Signal integrity with excellent 360° EMC shielding

- Long life cycles with durable materials and mechanical designs resisting up to 10,000 mating cycles

Requirements & challenges

Interconnect solutions for multiple source sensors and data management

- High data speeds and multi-protocol management including Single Pair Ethernet

- Size, weight and power (SWaP) optimization for compact devices in space-constrained areas

- Maximized functionality with high density and hybrid signal & power options

Interconnect solutions for multiple source sensors and data management

- High data speeds and multi-protocol management including Single Pair Ethernet

- Size, weight and power (SWaP) optimization for compact devices in space-constrained areas

- Maximized functionality with high density and hybrid signal & power options

Interconnect solutions for multiple source sensors and data management

- High data speeds and multi-protocol management including Single Pair Ethernet

- Size, weight and power (SWaP) optimization for compact devices in space-constrained areas

- Maximized functionality with high density and hybrid signal & power options

Resistance to harsh conditions

- High corrosion resistance with up to 1,000 hours of salt mist

- Easy cleaning and maintenance with IP68/IP69 sealing (even unmated)

- Operations in vacuum or pressurized environments with hermetic solutions

- Signal integrity with excellent 360° EMC shielding

- Long life cycles with durable materials and mechanical designs resisting up to 10,000 mating cycles

Resistance to harsh conditions

- High corrosion resistance with up to 1,000 hours of salt mist

- Easy cleaning and maintenance with IP68/IP69 sealing (even unmated)

- Operations in vacuum or pressurized environments with hermetic solutions

- Signal integrity with excellent 360° EMC shielding

- Long life cycles with durable materials and mechanical designs resisting up to 10,000 mating cycles

Resistance to harsh conditions

- High corrosion resistance with up to 1,000 hours of salt mist

- Easy cleaning and maintenance with IP68/IP69 sealing (even unmated)

- Operations in vacuum or pressurized environments with hermetic solutions

- Signal integrity with excellent 360° EMC shielding

- Long life cycles with durable materials and mechanical designs resisting up to 10,000 mating cycles

Related certifications

Typical applications

Production monitoring and data logging

Increasing the number of sensors and actuators on production lines in large-scale facilities and infrastructures calls for more cables and connections with various distance ranges. Fischer Cable Assembly Solutions seamlessly interconnect multiple production line modules with the rest of the organization’s network system.

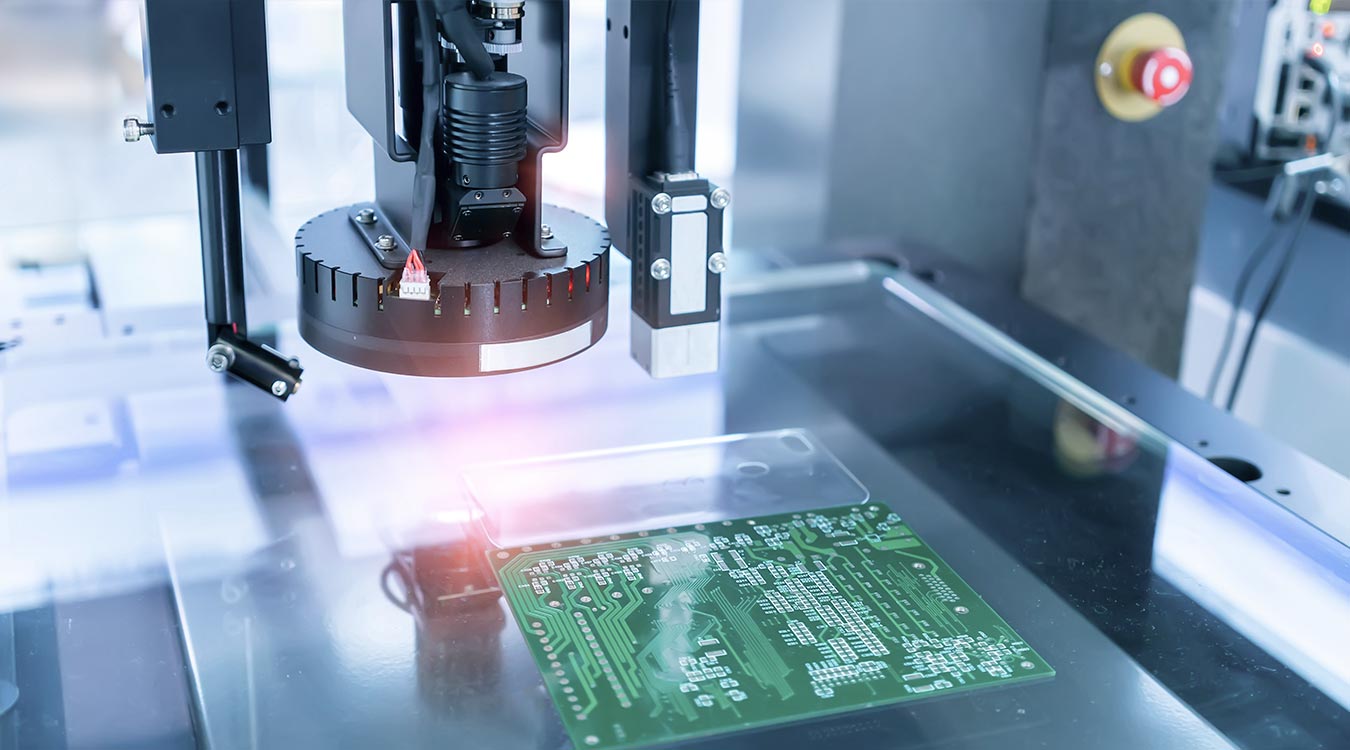

Vision and inspection systems

The systems inspecting production line modules may need to be connected in confined areas where minimal space is available for connectivity. The space saved by Fischer MiniMax™ solutions can amount to 45% compared to standard solutions.

Robotics arms

Robots used on the production line require extra flexibility of movement, which is easier to attain using Fischer Single Pair Ethernet connectivity solutions than with rigid Ethernet cables.