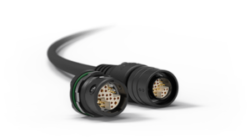

Military connectors

The sector of military electrical connectors places paramount importance on quality, reliability and durability, as military equipment is required to function in harsh and demanding environments.

In order to meet the rigorous demands of military operations, connectors must possess a high degree of resistance to environmental factors like dust, moisture and extreme temperatures, as well as the ability to withstand exposure to shock and vibration. In addition, they are required to comply with widely recognized international standards and soldier modernization programs to ensure optimal performance.

In order to meet the rigorous demands of military operations, connectors must possess a high degree of resistance to environmental factors like dust, moisture and extreme temperatures, as well as the ability to withstand exposure to shock and vibration. In addition, they are required to comply with widely recognized international standards and soldier modernization programs to ensure optimal performance.

In order to meet the rigorous demands of military operations, connectors must possess a high degree of resistance to environmental factors like dust, moisture and extreme temperatures, as well as the ability to withstand exposure to shock and vibration. In addition, they are required to comply with widely recognized international standards and soldier modernization programs to ensure optimal performance.

In order to meet the rigorous demands of military operations, connectors must possess a high degree of resistance to environmental factors like dust, moisture and extreme temperatures, as well as the ability to withstand exposure to shock and vibration. In addition, they are required to comply with widely recognized international standards and soldier modernization programs to ensure optimal performance.

In order to meet the rigorous demands of military operations, connectors must possess a high degree of resistance to environmental factors like dust, moisture and extreme temperatures, as well as the ability to withstand exposure to shock and vibration. In addition, they are required to comply with widely recognized international standards and soldier modernization programs to ensure optimal performance.

In order to meet the rigorous demands of military operations, connectors must possess a high degree of resistance to environmental factors like dust, moisture and extreme temperatures, as well as the ability to withstand exposure to shock and vibration. In addition, they are required to comply with widely recognized international standards and soldier modernization programs to ensure optimal performance.

In order to meet the rigorous demands of military operations, connectors must possess a high degree of resistance to environmental factors like dust, moisture and extreme temperatures, as well as the ability to withstand exposure to shock and vibration. In addition, they are required to comply with widely recognized international standards and soldier modernization programs to ensure optimal performance.

In order to meet the rigorous demands of military operations, connectors must possess a high degree of resistance to environmental factors like dust, moisture and extreme temperatures, as well as the ability to withstand exposure to shock and vibration. In addition, they are required to comply with widely recognized international standards and soldier modernization programs to ensure optimal performance.

In order to meet the rigorous demands of military operations, connectors must possess a high degree of resistance to environmental factors like dust, moisture and extreme temperatures, as well as the ability to withstand exposure to shock and vibration. In addition, they are required to comply with widely recognized international standards and soldier modernization programs to ensure optimal performance.

Sales request

Get STEP files and product information

Latest product releases

Latest product releases

Latest product releases

Ratchet Locking System

Fischer Connectors’ new Ratchet locking system enhances the UltiMate™ family with unmatched vibration resistance for the most demanding field operations. The ratcheting mechanism delivers secure locking that keeps signals stable even in high-motion environments. Tested to 37.8 Grms in random vibration (wide spectrum of frequencies occurring simultaneously) and 30 g for 12 hours in sine vibration (single-frequency, periodic waveform), the Ratchet system is engineered to maintain secure connections under extreme, continuous stress.

Proven on vibration profiles typical of armored vehicles, heavy UAVs, and rail systems, it reliably prevents accidental unmating caused by shock, recoil, off-road mobility, or turbulence.

Fischer Connectors’ new Ratchet locking system enhances the UltiMate™ family with unmatched vibration resistance for the most demanding field operations. The ratcheting mechanism delivers secure locking that keeps signals stable even in high-motion environments. Tested to 37.8 Grms in random vibration (wide spectrum of frequencies occurring simultaneously) and 30 g for 12 hours in sine vibration (single-frequency, periodic waveform), the Ratchet system is engineered to maintain secure connections under extreme, continuous stress.

Proven on vibration profiles typical of armored vehicles, heavy UAVs, and rail systems, it reliably prevents accidental unmating caused by shock, recoil, off-road mobility, or turbulence.

Fischer Connectors’ new Ratchet locking system enhances the UltiMate™ family with unmatched vibration resistance for the most demanding field operations. The ratcheting mechanism delivers secure locking that keeps signals stable even in high-motion environments. Tested to 37.8 Grms in random vibration (wide spectrum of frequencies occurring simultaneously) and 30 g for 12 hours in sine vibration (single-frequency, periodic waveform), the Ratchet system is engineered to maintain secure connections under extreme, continuous stress.

Proven on vibration profiles typical of armored vehicles, heavy UAVs, and rail systems, it reliably prevents accidental unmating caused by shock, recoil, off-road mobility, or turbulence.

USB-C standard

Fischer Connectors has unveiled the UltiMate™ USB‑C connector, merging the USB‑C standard with industrial-grade durability. Engineered for extreme environments—from defense and mining to motorsports and railways—the connector delivers USB 3.2 Gen 1×2 speeds (up to 10 Gb/s) while withstanding intense vibration, severe shocks, and corrosion.

It features tool-free, glove-friendly ratchet coupling, IP68/ hermetic sealing, 360° EMI shielding, –30 °C to +80 °C operation, 3,000 mating cycles, and robust salt‑mist resistance. This rugged yet standardized solution ensures reliable, high-speed power and data connectivity in demanding mission-critical applications.

Fischer Connectors has unveiled the UltiMate™ USB‑C connector, merging the USB‑C standard with industrial-grade durability. Engineered for extreme environments—from defense and mining to motorsports and railways—the connector delivers USB 3.2 Gen 1×2 speeds (up to 10 Gb/s) while withstanding intense vibration, severe shocks, and corrosion.

It features tool-free, glove-friendly ratchet coupling, IP68/ hermetic sealing, 360° EMI shielding, –30 °C to +80 °C operation, 3,000 mating cycles, and robust salt‑mist resistance. This rugged yet standardized solution ensures reliable, high-speed power and data connectivity in demanding mission-critical applications.

Fischer Connectors has unveiled the UltiMate™ USB‑C connector, merging the USB‑C standard with industrial-grade durability. Engineered for extreme environments—from defense and mining to motorsports and railways—the connector delivers USB 3.2 Gen 1×2 speeds (up to 10 Gb/s) while withstanding intense vibration, severe shocks, and corrosion.

It features tool-free, glove-friendly ratchet coupling, IP68/ hermetic sealing, 360° EMI shielding, –30 °C to +80 °C operation, 3,000 mating cycles, and robust salt‑mist resistance. This rugged yet standardized solution ensures reliable, high-speed power and data connectivity in demanding mission-critical applications.

Our military connector solutions

Fischer Connectors has the innovation skills to capture the military advantages of digital technology, the agility to work on accelerated army timelines, and the rigorous attention to detail in design and manufacturing to meet the most stringent army requirements.

Our Swiss-made military connectors combine the ruggedness and the density needed for high-performance connectivity solutions managing data, signal and power in the field. Fischer Connectors’ series delivering up to 10 Amps on AWG 22 can provide you with the high current necessary to fast charge your rugged devices.

Furthermore, our military connectors have been designed to meet MIL-SPEC standards so that they are intermateable with other military connectors and can be easily integrated into military devices.

Fischer Connectors has the innovation skills to capture the military advantages of digital technology, the agility to work on accelerated army timelines, and the rigorous attention to detail in design and manufacturing to meet the most stringent army requirements.

Our Swiss-made military connectors combine the ruggedness and the density needed for high-performance connectivity solutions managing data, signal and power in the field. Fischer Connectors’ series delivering up to 10 Amps on AWG 22 can provide you with the high current necessary to fast charge your rugged devices.

Furthermore, our military connectors have been designed to meet MIL-SPEC standards so that they are intermateable with other military connectors and can be easily integrated into military devices.

Fischer Connectors has the innovation skills to capture the military advantages of digital technology, the agility to work on accelerated army timelines, and the rigorous attention to detail in design and manufacturing to meet the most stringent army requirements.

Our Swiss-made military connectors combine the ruggedness and the density needed for high-performance connectivity solutions managing data, signal and power in the field. Fischer Connectors’ series delivering up to 10 Amps on AWG 22 can provide you with the high current necessary to fast charge your rugged devices.

Furthermore, our military connectors have been designed to meet MIL-SPEC standards so that they are intermateable with other military connectors and can be easily integrated into military devices.

Key features

- Tested to IEC, EIA, MIL-STD-202, MIL-STD-810

- Designed to meet GOSSRA (Generic Open Soldier System Reference Architecture) and compatible with Nett Warrior components

- Compatible with NATO STANAG 4695 and 4851

- Extreme shock and vibration resistance

- High corrosion resistance (up to 1,000 hours of salt mist)

- Operating temperatures from -55 °C to +135 °C

- IP68 to IP69 and available with resin-sealed contact block

- Hermetic (gas tight, vacuum tight)

- 360° EMC shielding

- Blind mating

- Up to 10,000 mating cycles

Making the power and data connections that enable digital transformation is the core skill of Fischer Connectors. Our dedicated engineers will help you to precisely define the requirements of your project and will assist you during the whole development process.

Making the power and data connections that enable digital transformation is the core skill of Fischer Connectors. Our dedicated engineers will help you to precisely define the requirements of your project and will assist you during the whole development process.

Making the power and data connections that enable digital transformation is the core skill of Fischer Connectors. Our dedicated engineers will help you to precisely define the requirements of your project and will assist you during the whole development process.

Our product range

Our product range

Our product range

Our custom connector capabilities will help you meet your needs.

The military standards we focus on

Our military connectors comply with the following international standards covering various aspects of design, development and testing.

Our military connectors comply with the following international standards covering various aspects of design, development and testing.

Our military connectors comply with the following international standards covering various aspects of design, development and testing.

MIL-SPEC standards

MIL-SPEC or MilSpecs are a set of standards and guidelines established by the U.S. Department of Defense to ensure consistency and quality across various military-related products and services. These standards cover a wide range of products, providing detailed requirements for materials, construction, performance, testing and quality control, and sometimes including specific tests and evaluations.

Most of our products comply with MIL-STD-202, a standard that tests the components under stress conditions (vibration, shock, thermal shock, salt spray, humidity, altitude), as well as MIL-STD-810, which tests not just the components, but the complete system or solution.

GOSSRA

GOSSRA (Generic Open Soldier System Reference Architecture) is an open architecture framework that provides a standardized approach for the development and integration of soldier-worn systems, including wearable technologies, sensors and other equipment used by soldiers on the battlefield.

GOSSRA was developed by the U.S. Army’s Communications-Electronics Research, Development and Engineering Center (CERDEC) to establish a common, interoperable platform.

Soldier Modernization

The Soldier Modernization program aims to enhance the capabilities and effectiveness of individual soldiers by integrating advanced technologies and equipment into their gear. It focuses on improving areas such as personal protection, situational awareness, communication and firepower.

The program is to optimize soldier performance and survivability on the modern battlefield through the adoption of cutting-edge tools, systems, and equipment.

Nett Warrior

Nett Warrior is a dismounted soldier system from the U.S. Army that provides enhanced situational awareness, mission planning and communication capabilities to individual soldiers on the battlefield. It is a wearable technology system that allows soldiers to exchange real-time information with other members of their unit and higher headquarters, providing them with a common operational picture of the battlefield.

The Nett Warrior program has developed a set of standards that define the technical requirements for the hardware and software components of the system. Our UltiMate 80 connectors have been designed to be compatible with Nett Warrior components.

NATO STANAG 4695 and 4851

NATO member countries use the NATO Standardization Agreement (STANAG) to meet a common set of technical requirements ensuring interoperability and compatibility in joint military operations. NATO STANAG 4695 is the agreement providing electrical connectivity standards for soldier power connectors, employed between NATO power sources and dismounted soldier systems.

NATO STANAG 4851 allows for effective communication and coordination through radio communication systems, specifying the technical requirements for voice and data transmission, encryption and signal modulation. Fischer UltiMate™ 80 connectors and cable assemblies have been designed to meet both NATO STANAG 4696 and 4851 standards.

Our dedicated model: Fischer UltiMate™ 80

Designed to meet NATO STANAG 4695/4851, GOSSRA and Soldier Modernization requirements and to be compatible with Nett Warrior components, the Fischer UltiMate™ 80 connector outperforms most of the competitors on the defense market in terms of durability, as well as environmental and mechanical performance.

Designed to meet NATO STANAG 4695/4851, GOSSRA and Soldier Modernization requirements and to be compatible with Nett Warrior components, the Fischer UltiMate™ 80 connector outperforms most of the competitors on the defense market in terms of durability, as well as environmental and mechanical performance.

Designed to meet NATO STANAG 4695/4851, GOSSRA and Soldier Modernization requirements and to be compatible with Nett Warrior components, the Fischer UltiMate™ 80 connector outperforms most of the competitors on the defense market in terms of durability, as well as environmental and mechanical performance.

With its rugged construction and advanced features, the UltiMate 80 provides a reliable and secure connection for data, signal and power transmission in harsh environments and extreme conditions. The Ultimate 80 features a robust and ergonomic design that can withstand exposure to shock, vibration, dust, moisture and extreme temperatures – perfectly suited for devices and equipment worn by dismounted soldiers in the field.

Fischer UltiMate 80™ comes in two layouts featuring 6 or 7 signal and power contacts with up to AWG 22.

Available in straight or right-angle overmolding.

Interested in Fischer UltiMate™ 80?

With its rugged construction and advanced features, the UltiMate 80 provides a reliable and secure connection for data, signal and power transmission in harsh environments and extreme conditions. The Ultimate 80 features a robust and ergonomic design that can withstand exposure to shock, vibration, dust, moisture and extreme temperatures – perfectly suited for devices and equipment worn by dismounted soldiers in the field.

Fischer UltiMate 80™ comes in two layouts featuring 6 or 7 signal and power contacts with up to AWG 22.

Available in straight or right-angle overmolding.

Interested in Fischer UltiMate™ 80?

With its rugged construction and advanced features, the UltiMate 80 provides a reliable and secure connection for data, signal and power transmission in harsh environments and extreme conditions. The Ultimate 80 features a robust and ergonomic design that can withstand exposure to shock, vibration, dust, moisture and extreme temperatures – perfectly suited for devices and equipment worn by dismounted soldiers in the field.

Fischer UltiMate 80™ comes in two layouts featuring 6 or 7 signal and power contacts with up to AWG 22.

Available in straight or right-angle overmolding.

Interested in Fischer UltiMate™ 80?

High-performance MIL-SPEC connector applications

Here are some examples of applications where our military circular connectors are trusted to endure challenging conditions in the field.

Here are some examples of applications where our military circular connectors are trusted to endure challenging conditions in the field.

Here are some examples of applications where our military circular connectors are trusted to endure challenging conditions in the field.

Night vision goggles

Night vision goggles rely on advanced electronic components and sensors to function properly, and the miniaturization of components is a critical aspect of this device, to ensure comfortable wear for extended periods of time.

For soldiers, the goggles are essential to maintain situational awareness and communicate effectively with their team members.

Night vision goggles

Night vision goggles rely on advanced electronic components and sensors to function properly, and the miniaturization of components is a critical aspect of this device, to ensure comfortable wear for extended periods of time.

For soldiers, the goggles are essential to maintain situational awareness and communicate effectively with their team members.

Night vision goggles

Night vision goggles rely on advanced electronic components and sensors to function properly, and the miniaturization of components is a critical aspect of this device, to ensure comfortable wear for extended periods of time.

For soldiers, the goggles are essential to maintain situational awareness and communicate effectively with their team members.

Tactical computers

Tactical computers must be able to operate in harsh environments and conditions such as shocks, vibrations, extreme temperatures and dusty or wet areas. Military connectors enable tactical computers to maintain their performances. They are made of rugged materials such as stainless steel or aluminum, and feature ruggedized seals and coatings for maximal protection.

They also provide higher data transfer rates and greater bandwidth than traditional connectors. This allows for faster and more efficient data transmission, which is critical in tactical applications where speed and accuracy are essential.

Tactical computers

Tactical computers must be able to operate in harsh environments and conditions such as shocks, vibrations, extreme temperatures and dusty or wet areas. Military connectors enable tactical computers to maintain their performances. They are made of rugged materials such as stainless steel or aluminum, and feature ruggedized seals and coatings for maximal protection.

They also provide higher data transfer rates and greater bandwidth than traditional connectors. This allows for faster and more efficient data transmission, which is critical in tactical applications where speed and accuracy are essential.

Tactical computers

Tactical computers must be able to operate in harsh environments and conditions such as shocks, vibrations, extreme temperatures and dusty or wet areas. Military connectors enable tactical computers to maintain their performances. They are made of rugged materials such as stainless steel or aluminum, and feature ruggedized seals and coatings for maximal protection.

They also provide higher data transfer rates and greater bandwidth than traditional connectors. This allows for faster and more efficient data transmission, which is critical in tactical applications where speed and accuracy are essential.

Data & power hub

Wearable data and power hubs are devices that provide a centralized point for managing body-worn electronics. These hubs are typically designed to be rugged, lightweight and compact so as to integrate seamlessly into soldiers’ equipment.

Comprising a multiport tactical hub, a power management app and customized cable assembly solutions, Fischer KEYSTONE™ is the complete solution to the connectivity challenge in the battlefield.

Data & power hub

Wearable data and power hubs are devices that provide a centralized point for managing body-worn electronics. These hubs are typically designed to be rugged, lightweight and compact so as to integrate seamlessly into soldiers’ equipment.

Comprising a multiport tactical hub, a power management app and customized cable assembly solutions, Fischer KEYSTONE™ is the complete solution to the connectivity challenge in the battlefield.

Data & power hub

Wearable data and power hubs are devices that provide a centralized point for managing body-worn electronics. These hubs are typically designed to be rugged, lightweight and compact so as to integrate seamlessly into soldiers’ equipment.

Comprising a multiport tactical hub, a power management app and customized cable assembly solutions, Fischer KEYSTONE™ is the complete solution to the connectivity challenge in the battlefield.

The path of optimization

Modernization initiatives are increasingly centered on maximizing how well soldiers and small units can share and process information using cutting-edge digital technologies. The “digital revolution in military affairs” is occurring as four major technologies have matured: artificial intelligence, augmented reality, miniaturized affordable sensors, and efficient wearable power supply. These four critical technologies create unprecedented demands for connections capable of handling massive volumes of data with minimal power and weight.

High-density military connectors are typically used in applications where space is at a premium, such as in portable electronic devices and aerospace and defense systems. By packing more contacts into a smaller connector, they can help reduce the size and weight of electronic systems while still providing all the necessary connections.

Modernization initiatives are increasingly centered on maximizing how well soldiers and small units can share and process information using cutting-edge digital technologies. The “digital revolution in military affairs” is occurring as four major technologies have matured: artificial intelligence, augmented reality, miniaturized affordable sensors, and efficient wearable power supply. These four critical technologies create unprecedented demands for connections capable of handling massive volumes of data with minimal power and weight.

High-density military connectors are typically used in applications where space is at a premium, such as in portable electronic devices and aerospace and defense systems. By packing more contacts into a smaller connector, they can help reduce the size and weight of electronic systems while still providing all the necessary connections.

Modernization initiatives are increasingly centered on maximizing how well soldiers and small units can share and process information using cutting-edge digital technologies. The “digital revolution in military affairs” is occurring as four major technologies have matured: artificial intelligence, augmented reality, miniaturized affordable sensors, and efficient wearable power supply. These four critical technologies create unprecedented demands for connections capable of handling massive volumes of data with minimal power and weight.

High-density military connectors are typically used in applications where space is at a premium, such as in portable electronic devices and aerospace and defense systems. By packing more contacts into a smaller connector, they can help reduce the size and weight of electronic systems while still providing all the necessary connections.

The advantages brought by these breakthrough technologies on the battlefield are numerous. Unlike a new warhead whose accuracy or penetration is easy to measure, the effectiveness of soldier-worn systems is assessed against different criteria. These systems enable soldiers to process and access a wide range of information, and their advantage lies in the quality and speed of the decisions made by individual soldiers and by commanders at every level.

To fully leverage the potential of these revolutionary technologies, soldier-worn technology needs to collect and disseminate information efficiently, i.e., in gaining and maintaining seamless ‘connectivity’ throughout every stage of the decision-making cycle.

The advantages brought by these breakthrough technologies on the battlefield are numerous. Unlike a new warhead whose accuracy or penetration is easy to measure, the effectiveness of soldier-worn systems is assessed against different criteria. These systems enable soldiers to process and access a wide range of information, and their advantage lies in the quality and speed of the decisions made by individual soldiers and by commanders at every level.

To fully leverage the potential of these revolutionary technologies, soldier-worn technology needs to collect and disseminate information efficiently, i.e., in gaining and maintaining seamless ‘connectivity’ throughout every stage of the decision-making cycle.

The advantages brought by these breakthrough technologies on the battlefield are numerous. Unlike a new warhead whose accuracy or penetration is easy to measure, the effectiveness of soldier-worn systems is assessed against different criteria. These systems enable soldiers to process and access a wide range of information, and their advantage lies in the quality and speed of the decisions made by individual soldiers and by commanders at every level.

To fully leverage the potential of these revolutionary technologies, soldier-worn technology needs to collect and disseminate information efficiently, i.e., in gaining and maintaining seamless ‘connectivity’ throughout every stage of the decision-making cycle.