Fischer Core Series

With more than 20,000 standard circular connectors and highly customizable contact configurations, the Fischer Core Series offers an extremely versatile variety of high-performance push-pull connectors

ANY SIZE | ANY CONFIGURATION | ANY APPLICATION

ANY SIZE | ANY CONFIGURATION | ANY APPLICATION

ANY SIZE | ANY CONFIGURATION | ANY APPLICATION

ANY SIZE | ANY CONFIGURATION | ANY APPLICATION

ANY SIZE | ANY CONFIGURATION | ANY APPLICATION

ANY SIZE | ANY CONFIGURATION | ANY APPLICATION

ANY SIZE | ANY CONFIGURATION | ANY APPLICATION

ANY SIZE | ANY CONFIGURATION | ANY APPLICATION

ANY SIZE | ANY CONFIGURATION | ANY APPLICATION

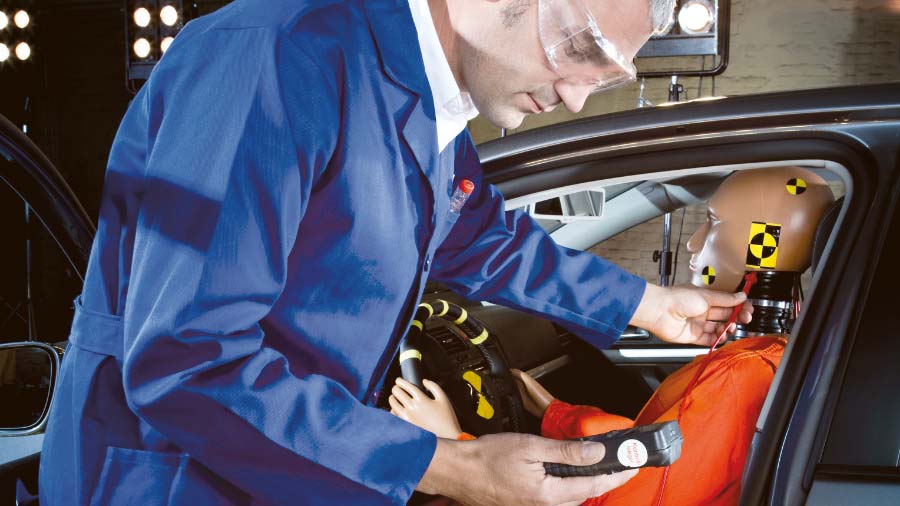

Rugged, reliable, sealed or hermetic, lightweight and compact. The Fischer Core Series is trusted by technology-driven industries worldwide, from medical, defense and industrial automation, to test & measurement equipment.

Rugged, reliable, sealed or hermetic, lightweight and compact. The Fischer Core Series is trusted by technology-driven industries worldwide, from medical, defense and industrial automation, to test & measurement equipment.

Rugged, reliable, sealed or hermetic, lightweight and compact. The Fischer Core Series is trusted by technology-driven industries worldwide, from medical, defense and industrial automation, to test & measurement equipment.

Rugged, reliable, sealed or hermetic, lightweight and compact. The Fischer Core Series is trusted by technology-driven industries worldwide, from medical, defense and industrial automation, to test & measurement equipment.

Rugged, reliable, sealed or hermetic, lightweight and compact. The Fischer Core Series is trusted by technology-driven industries worldwide, from medical, defense and industrial automation, to test & measurement equipment.

Rugged, reliable, sealed or hermetic, lightweight and compact. The Fischer Core Series is trusted by technology-driven industries worldwide, from medical, defense and industrial automation, to test & measurement equipment.

Rugged, reliable, sealed or hermetic, lightweight and compact. The Fischer Core Series is trusted by technology-driven industries worldwide, from medical, defense and industrial automation, to test & measurement equipment.

Rugged, reliable, sealed or hermetic, lightweight and compact. The Fischer Core Series is trusted by technology-driven industries worldwide, from medical, defense and industrial automation, to test & measurement equipment.

Rugged, reliable, sealed or hermetic, lightweight and compact. The Fischer Core Series is trusted by technology-driven industries worldwide, from medical, defense and industrial automation, to test & measurement equipment.

Key features

High-performance and robust

- High sealing performances for vacuum and underwater applications

- Operating temperatures from -70 °C to +250 °C

- Chemical resistance and sterilization proof

- Corrosion resistance

- Up to 10,000 mating cycles

Wide product choice

- Large number of configurations

- Low/high voltage, coax/triax, hybrid versions

- Lightweight aluminum and plastic versions

- Disposable versions

Key features

High-performance and robust

- High sealing performances for vacuum and underwater applications

- Operating temperatures from -70 °C to +250 °C

- Chemical resistance and sterilization proof

- Corrosion resistance

- Up to 10,000 mating cycles

Wide product choice

- Large number of configurations

- Low/high voltage, coax/triax, hybrid versions

- Lightweight aluminum and plastic versions

- Disposable versions

Key features

High-performance and robust

- High sealing performances for vacuum and underwater applications

- Operating temperatures from -70 °C to +250 °C

- Chemical resistance and sterilization proof

- Corrosion resistance

- Up to 10,000 mating cycles

Wide product choice

- Large number of configurations

- Low/high voltage, coax/triax, hybrid versions

- Lightweight aluminum and plastic versions

- Disposable versions

Sales request

Get STEP files and product information

Core series overview

ANY SIZE

ANY CONFIGURATION

ANY APPLICATION

| Hermetic

HIGH CORROSION RESISTANCE

EASY DECONTAMINATION

EASY HANDLING

| Hermetic

ULTRALIGHT

RUGGED

HIGHLY CONFIGURABLE

| Hermetic

EASY TO USE

DURABLE

LIGHTWEIGHT

COST-EFFECTIVE

EASY TO USE

MODULAR

THE BEST OF TRIAX

RUGGED

FOR OUTDOOR USE

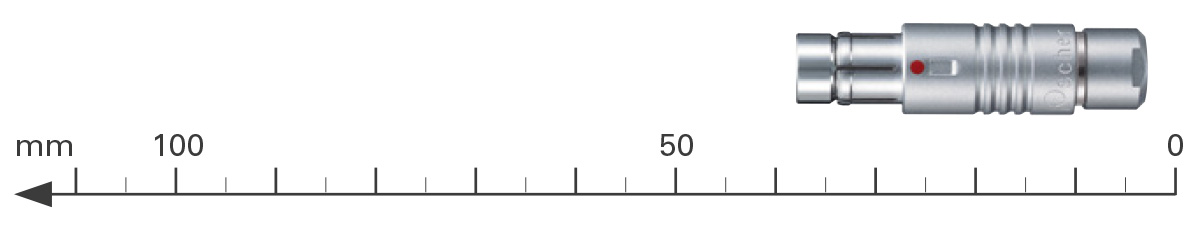

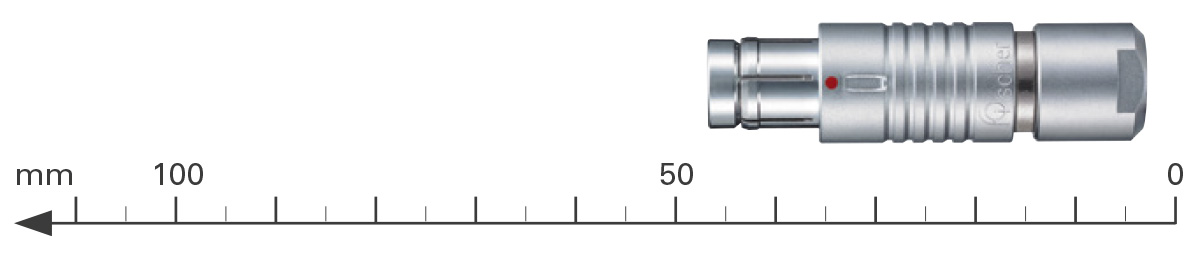

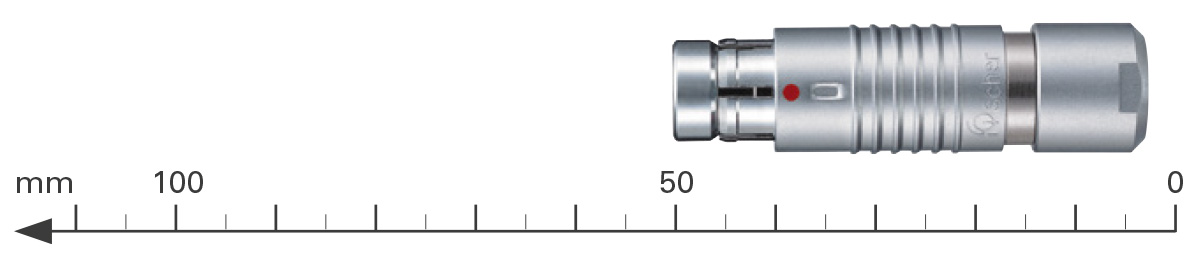

Connector size vs. cable diameter

| Multipole low voltage | Multipole high voltage | Coax low voltage | Coax high voltage | Triax | Mixed high voltage | Mixed coax | ||||||||||||||||||||

| Series | Min Cable ø | Max Cable ø | Nbr of Contacts | Min Cable ø | Max Cable ø | Nbr of Contacts | Min Cable ø | Max Cable ø | Min Cable ø | Max Cable ø | Min Cable ø | Max Cable ø | Min Cable ø | Max Cable ø | Nbr of Contacts | Min Cable ø | Max Cable ø | Nbr of Contacts | ||||||||

|

102 | 1.5 |

4.7 (4.3)2) |

2-9 | 1.5 | 4.7 (4.3) | 1.5 | 4.7 (4.3) | 1.5 | 4.7 (4.3) | ||||||||||||||||

|

103 | 1.7 |

6.7 (6.2)2) |

2-12 | 1.7 | 6.7 (6.2) | 1.7 | 6.7 (6.2) | 1.7 | 6.7 (6.2) | ||||||||||||||||

|

1031 | 2.2 |

7.2 (6.7)2) |

10-19 | ||||||||||||||||||||||

|

104 | 2.9 | 8.7 | 2-27 | 2.9 | 8.7 | 4 HV | 2.9 | 8.7 | 2.9 | 8.7 | 2.9 | 8.7 |

1 LV

2 HV |

2.9 | 8.7 |

1 Coax

1-4 LV |

|||||||||

|

105 | 1.5 | 10.7 | 2-27 | 3.2 | 10.7 | 3-5 HV | 3.2 | 10.7 | 3.2 | 10.7 | 3.2 | 10.7 |

1-10 LV

1-4 HV |

3.2 | 10.7 |

1 Coax

1-9 LV |

|||||||||

|

106 | 4.2 | 19.2 | 3-24 | 4.2 | 19.2 | 6-7 HV | 4.2 | 19.2 |

6 LV

2 HV |

||||||||||||||||

|

107 | 5.7 | 22.7 | 4-55 | 5.7 | 22.7 | 7 HV | 5.7 | 22.7 | |||||||||||||||||

| Multipole low voltage | Multipole high voltage | Coax low voltage | Coax high voltage | Triax | Mixed high voltage | Mixed coax | ||||||||||||||||||||

| Series | Min Cable ø | Max Cable ø | Nbr of Contacts | Min Cable ø | Max Cable ø | Nbr of Contacts | Min Cable ø | Max Cable ø | Min Cable ø | Max Cable ø | Min Cable ø | Max Cable ø | Min Cable ø | Max Cable ø | Nbr of Contacts | Min Cable ø | Max Cable ø | Nbr of Contacts | ||||||||

|

102 | 1.5 |

4.7 (4.3)2) |

2-9 | 1.5 | 4.7 (4.3) | 1.5 | 4.7 (4.3) | 1.5 | 4.7 (4.3) | ||||||||||||||||

|

103 | 1.7 |

6.7 (6.2)2) |

2-12 | 1.7 | 6.7 (6.2) | 1.7 | 6.7 (6.2) | 1.7 | 6.7 (6.2) | ||||||||||||||||

|

1031 | 2.2 |

7.2 (6.7)2) |

10-19 | ||||||||||||||||||||||

|

104 | 2.9 | 8.7 | 2-27 | 2.9 | 8.7 | 4 HV | 2.9 | 8.7 | 2.9 | 8.7 | 2.9 | 8.7 |

1 LV

2 HV |

2.9 | 8.7 |

1 Coax

1-4 LV |

|||||||||

|

105 | 1.5 | 10.7 | 2-27 | 3.2 | 10.7 | 3-5 HV | 3.2 | 10.7 | 3.2 | 10.7 | 3.2 | 10.7 |

1-10 LV

1-4 HV |

3.2 | 10.7 |

1 Coax

1-9 LV |

|||||||||

|

106 | 4.2 | 19.2 | 3-24 | 4.2 | 19.2 | 6-7 HV | 4.2 | 19.2 |

6 LV

2 HV |

||||||||||||||||

|

107 | 5.7 | 22.7 | 4-55 | 5.7 | 22.7 | 7 HV | 5.7 | 22.7 | |||||||||||||||||

| Multipole low voltage | Multipole high voltage | Coax low voltage | Coax high voltage | Triax | Mixed high voltage | Mixed coax | ||||||||||||||||||||

| Series | Min Cable ø | Max Cable ø | Nbr of Contacts | Min Cable ø | Max Cable ø | Nbr of Contacts | Min Cable ø | Max Cable ø | Min Cable ø | Max Cable ø | Min Cable ø | Max Cable ø | Min Cable ø | Max Cable ø | Nbr of Contacts | Min Cable ø | Max Cable ø | Nbr of Contacts | ||||||||

|

102 | 1.5 |

4.7 (4.3)2) |

2-9 | 1.5 | 4.7 (4.3) | 1.5 | 4.7 (4.3) | 1.5 | 4.7 (4.3) | ||||||||||||||||

|

103 | 1.7 |

6.7 (6.2)2) |

2-12 | 1.7 | 6.7 (6.2) | 1.7 | 6.7 (6.2) | 1.7 | 6.7 (6.2) | ||||||||||||||||

|

1031 | 2.2 |

7.2 (6.7)2) |

10-19 | ||||||||||||||||||||||

|

104 | 2.9 | 8.7 | 2-27 | 2.9 | 8.7 | 4 HV | 2.9 | 8.7 | 2.9 | 8.7 | 2.9 | 8.7 |

1 LV

2 HV |

2.9 | 8.7 |

1 Coax

1-4 LV |

|||||||||

|

105 | 1.5 | 10.7 | 2-27 | 3.2 | 10.7 | 3-5 HV | 3.2 | 10.7 | 3.2 | 10.7 | 3.2 | 10.7 |

1-10 LV

1-4 HV |

3.2 | 10.7 |

1 Coax

1-9 LV |

|||||||||

|

106 | 4.2 | 19.2 | 3-24 | 4.2 | 19.2 | 6-7 HV | 4.2 | 19.2 |

6 LV

2 HV |

||||||||||||||||

|

107 | 5.7 | 22.7 | 4-55 | 5.7 | 22.7 | 7 HV | 5.7 | 22.7 | |||||||||||||||||

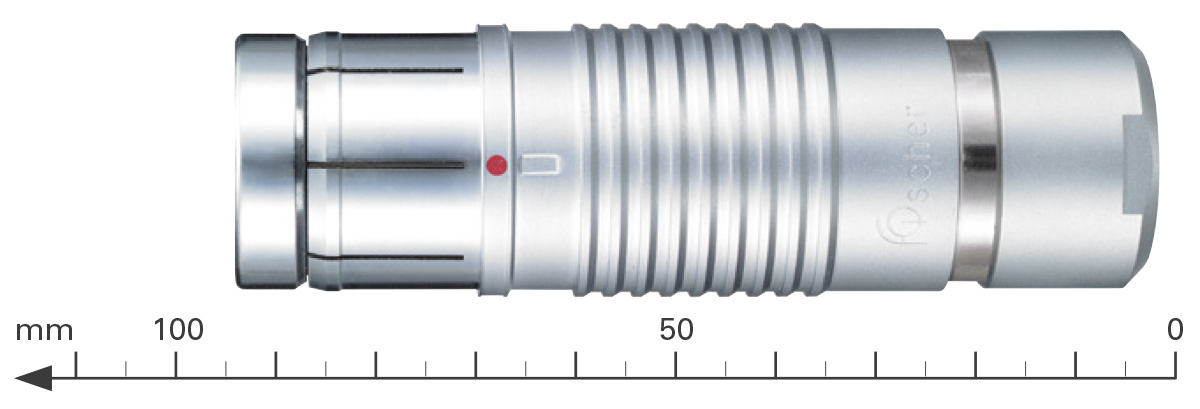

Product range

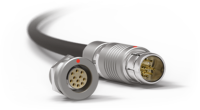

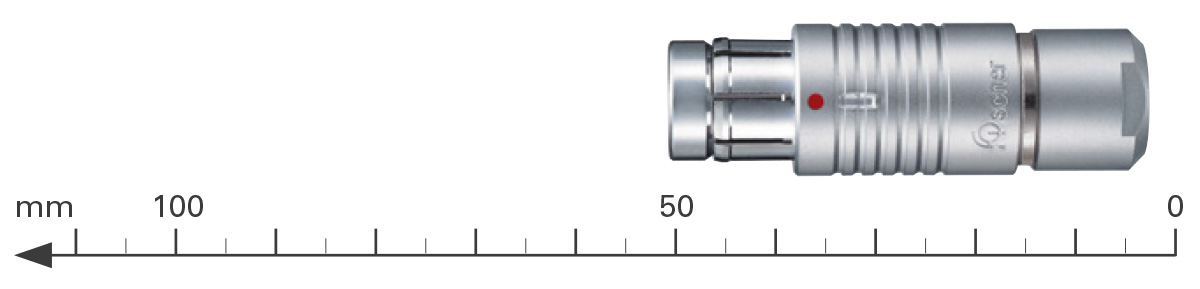

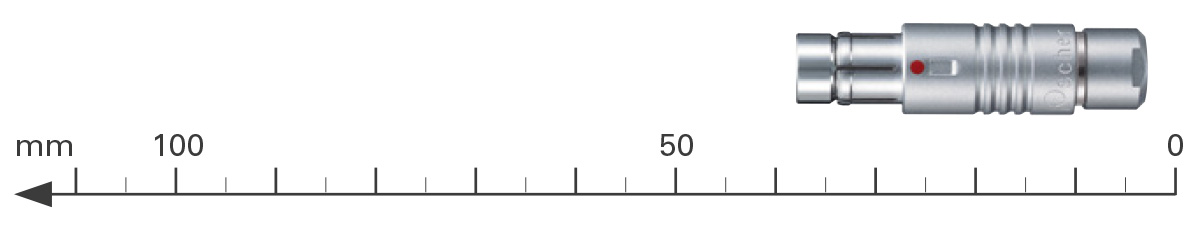

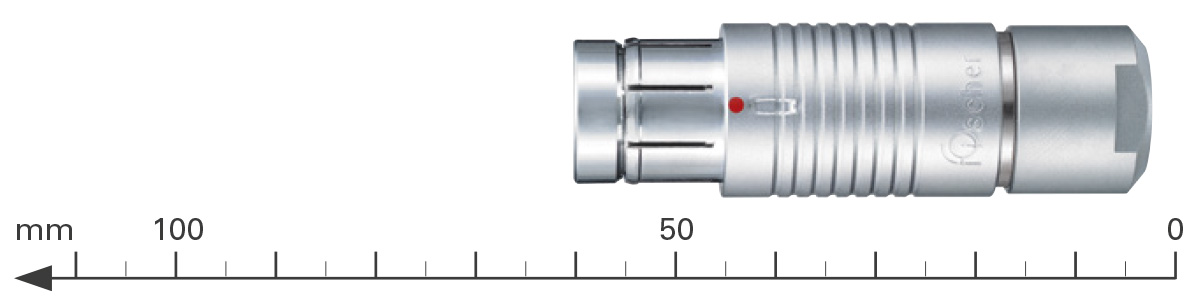

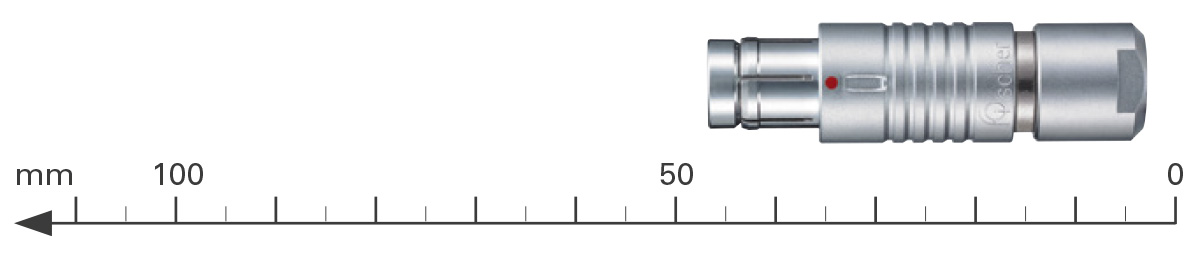

Fischer Core Series Brass

- Wide range of housing types and contact block variants

- Original standard push-pull locking system

- Up to IP68 sealing (liquid tight)

- Hermetic versions available (gas tight, vacuum tight)

- Resistant to autoclave sterilization

- 10,000 mating cycles

- Wide range of housing types and contact block variants

- Original standard push-pull locking system

- Up to IP68 sealing (liquid tight)

- Hermetic versions available (gas tight, vacuum tight)

- Resistant to autoclave sterilization

- 10,000 mating cycles

The first series of connectors developed by Fischer Connectors, featuring the original, revolutionary push-pull technology. With over 65 years of continuous improvements, this series includes over 20,000 standard circular connectors and offers highly customizable contact configurations. Used in multiple customer applications and demanding environments such as medical, instrumentation and defense & security.

| Characteristic | Product type | Value | Standard |

| Sealing performance | Unsealed connectors (mated) | IP50 | IEC 60529 |

|

Plug (mated) with general purpose sealed clamps 1) |

IP68

IP69 |

||

| Receptacles “U” body style | IP68 | ||

| Receptacles “E” body style |

Hermetic: Tested: <10-8 mbar l/sec. |

IEC 60068-2-17 test Qk method 3, alternative b | |

| IP69 | IEC 60529 | ||

| Operating temperature range | See details on tech spec V.1 | See details on tech spec V.1 | IEC 60512-6-11 i+j / IEC 60068-2-14-Nb |

|

Corrosion resistance 3) |

Salt mist, 1,000 hours, 5% salt solution, 35°C |

IEC 60068-2-11 test Ka MIL-STD-202 method 101 EIA-364-26 |

|

| Endurance | 10,000 mating cycles | IEC 60512-9-1 / EIA-364-09 | |

| Vibration | 10 to 2000 Hz, 1.5 mm or 15g, 12 sweep cycles per axis, 20 minutes per 10-2000-10 Hz sweep cycle, no discontinuity > 1us | MIL-STD-202 method 204 condition B | |

|

Radiation resistance 3) |

Unsealed connectors |

PEEK: 107 Gy(=1000M Rads) |

|

| Sealed receptacles “E” |

FPM (Viton®) O-rings: 105 Gy(=10M Rads) |

||

1)The sealing performance can be affected by the long term quality of the cable.

2) For information only. Not tested by Fischer Connectors.

3) Plug and receptacle in mated position or with cap when unmated. For Brass connectors only.

Aluminum version not recommended for Marine use. Preserved mechanical and electrical functionality. Visual aspect might be altered.

Most of our connectors are completely sterilizable in autoclave, Cidex® , EtO, gamma radiation, Steris® or Sterrad®. Please contact us for more details.

| Characteristic | Contact size | Typical values | Standard |

| Contact resistance 10,000 mating cycles |

ø 0.5 mm ø 0.7 mm ø 0.9 mm ø 1.3 mm ø 1.6 mm ø 2.3 mm ø 3.0 mm |

5.0 mΩ

5.0 mΩ

4.0 mΩ

2.5 mΩ

2.5 mΩ

2.5 mΩ

1.5 mΩ |

IEC 60512-2-1, Test 2a

IEC 60512-2-2, Test 2b |

| Insulation resistance |

> 1010Ω |

IEC 60512-3-1-3a Method C | |

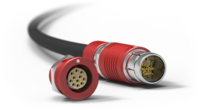

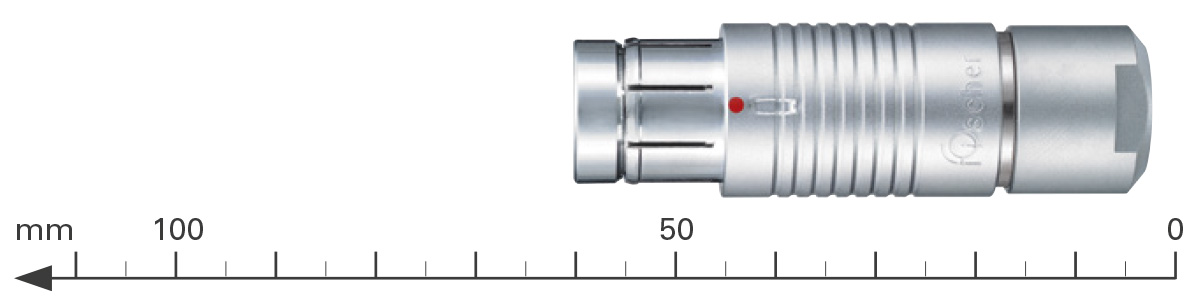

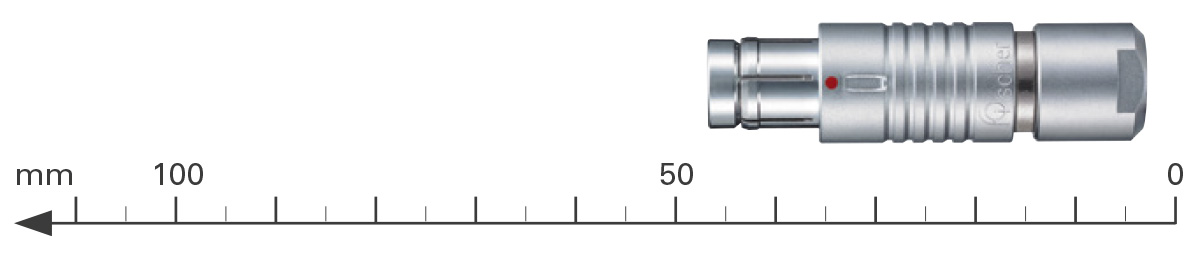

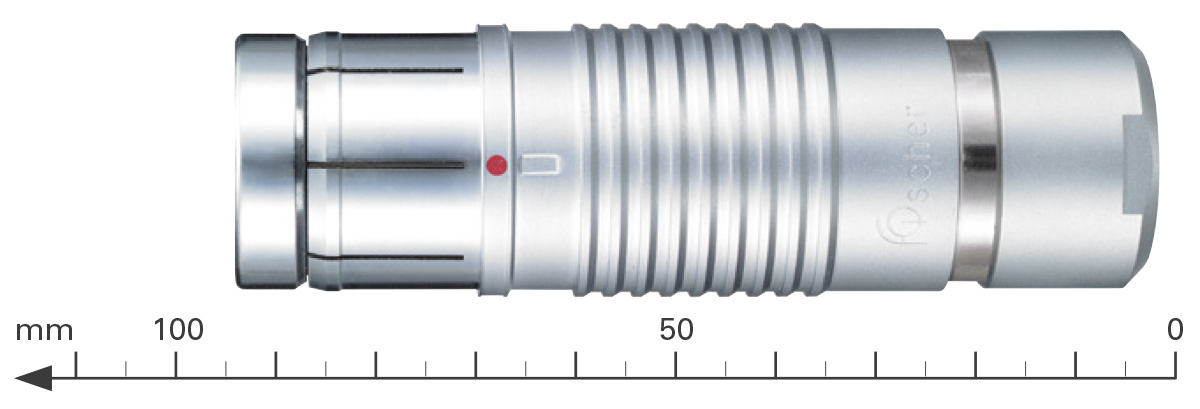

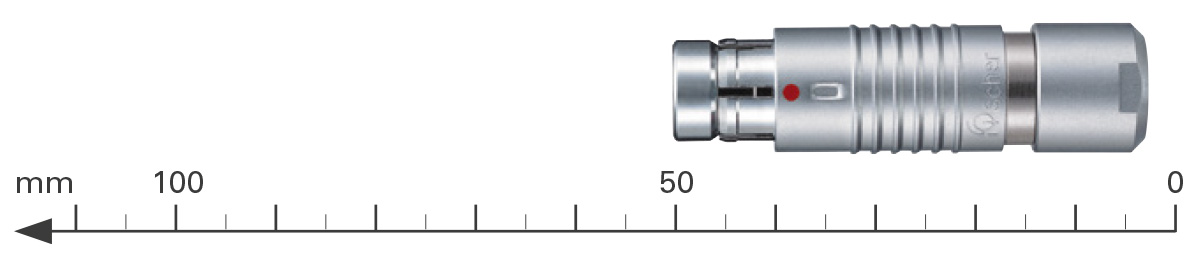

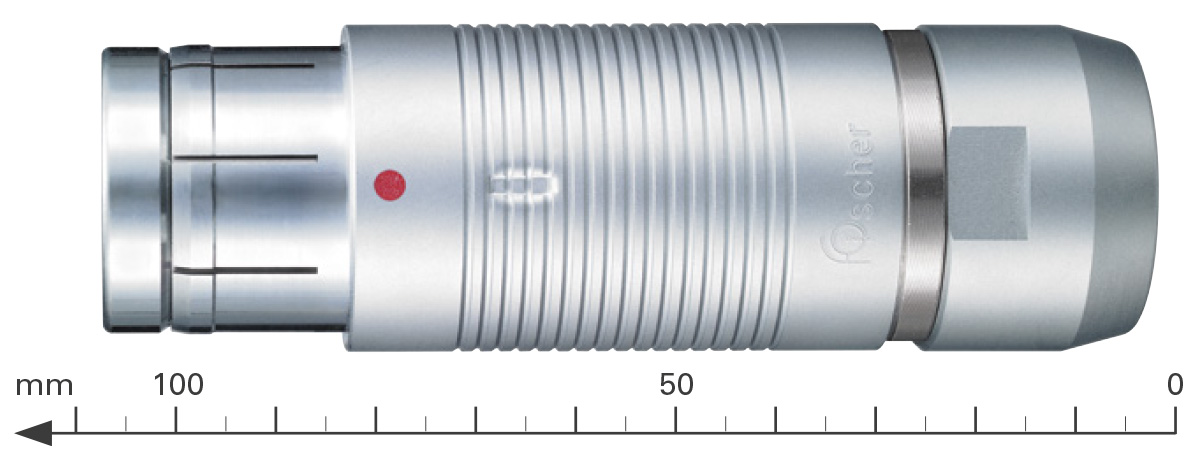

Fischer Core Series Stainless Steel

ULTRA RESISTANT | STERILIZABLE | EASY TO HANDLE

- Corrosion and radiation resistance

- Resistant to nuclear decontamination fluids

- Up to IP68 sealing (liquid tight)

- Hermetic versions available (gas tight, vacuum tight)

- High sterilization performance

- Easy to handle with gloves or remotely

- 5,000 mating cycles

- Corrosion and radiation resistance

- Resistant to nuclear decontamination fluids

- Up to IP68 sealing (liquid tight)

- Hermetic versions available (gas tight, vacuum tight)

- High sterilization performance

- Easy to handle with gloves or remotely

- 5,000 mating cycles

Made of premium-grade stainless steel, specially designed for high chemical, temperature and radiation resistance. Often used in nuclear research laboratories, nuclear waste management, but also in surgical environments and in the food processing industry, these connectors are easy to handle with gloves or remotely. With simple movements ensuring secure mating and unmating thanks to the industry-standard push-pull locking system, users can also operate in a glove box or use a teleoperator or a robot in hazardous or contaminated environments.

| Characteristic | Product type | Value | Standard |

| Sealing performance | Unsealed connectors (mated) | IP50 | IEC 60529 |

|

Plug (mated) with general purpose sealed clamps 1) |

IP68

IP69 |

||

| Receptacles “U” body style | IP68 | ||

| Receptacles “E” body style |

Hermetic: Tested: <10-8 mbar l/sec. |

IEC 60068-2-17 test Qk method 3, alternative b | |

| IP69 | IEC 60529 | ||

| Operating temperature range | See details on tech spec V.1 | See details on tech spec V.1 | IEC 60512-6-11 i+j / IEC 60068-2-14-Nb |

|

Corrosion resistance 3) |

Salt mist, 1,000 hours, 5% salt solution, 35°C |

IEC 60068-2-11 test Ka MIL-STD-202 method 101 condition A | |

| Endurance | 5,000 mating cycles | IEC 60512-9-1 / EIA-364-09 | |

| Vibration | 10 to 2000 Hz, 1.5 mm or 15g, 12 sweep cycles per axis, 20 minutes per 10-2000-10 Hz sweep cycle, no discontinuity > 1us | MIL-STD-202 method 204 condition B | |

|

Radiation resistance 3) |

Unsealed connectors |

PEEK: 107 Gy(=1000M Rads) |

|

| Sealed receptacles “E” |

FPM (Viton®) O-rings: 105 Gy(=10M Rads) |

||

1)The sealing performance can be affected by the long term quality of the cable. 2) For information only. Not tested by Fischer Connectors.

3) Plug and receptacle in mated position or with cap when unmated. For Brass connectors only.

Aluminum version not recommended for Marine use. Preserved mechanical and electrical functionality. Visual aspect might be altered.

Most of our connectors are completely sterilizable in autoclave, Cidex® , EtO, gamma radiation, Steris® or Sterrad®. Please contact us for more details.

| Characteristic | Contact size | Typical values | Standard |

| Contact resistance 10,000 mating cycles |

ø 0.5 mm ø 0.7 mm ø 0.9 mm ø 1.3 mm ø 1.6 mm ø 2.3 mm ø 3.0 mm |

5.0 mΩ

5.0 mΩ

4.0 mΩ

2.5 mΩ

2.5 mΩ

2.5 mΩ

1.5 mΩ |

IEC 60512-2-1, Test 2a

IEC 60512-2-2, Test 2b |

| Insulation resistance |

> 1010Ω |

IEC 60512-3-1-3a Method C | |

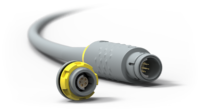

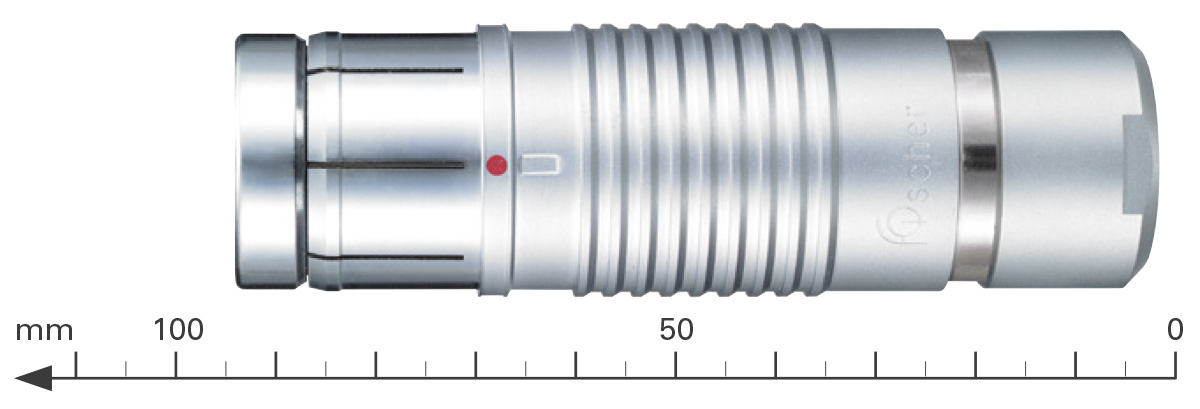

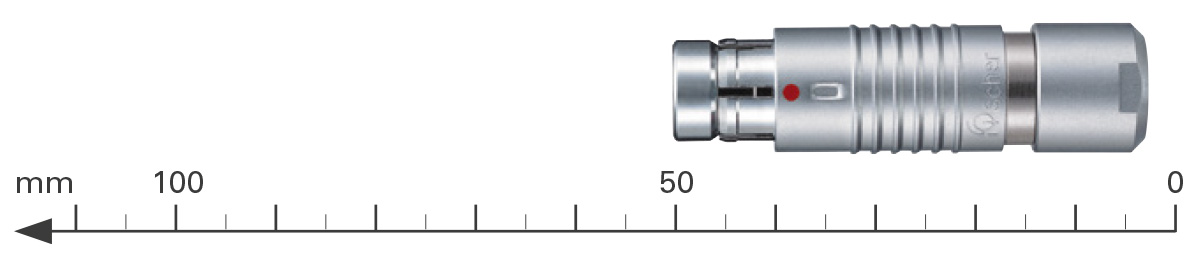

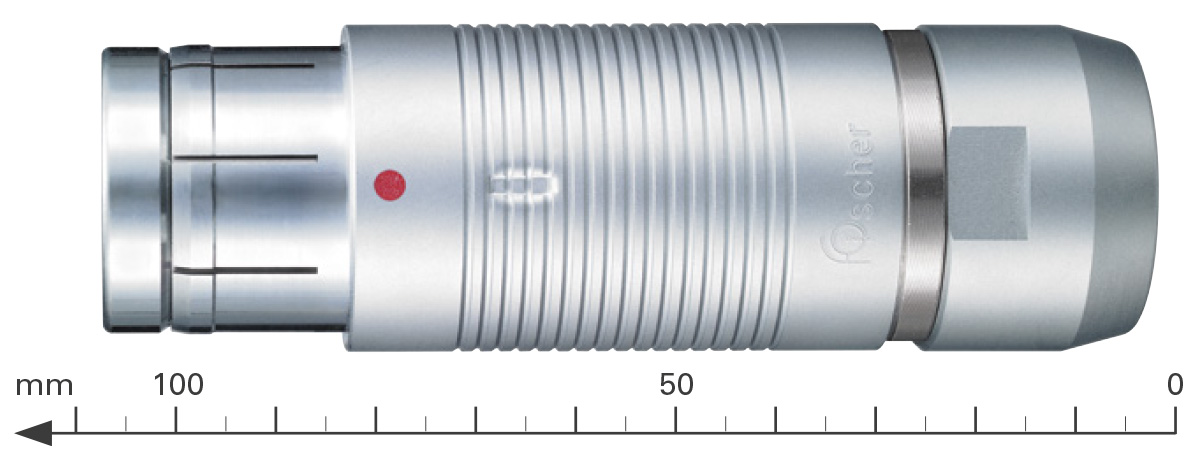

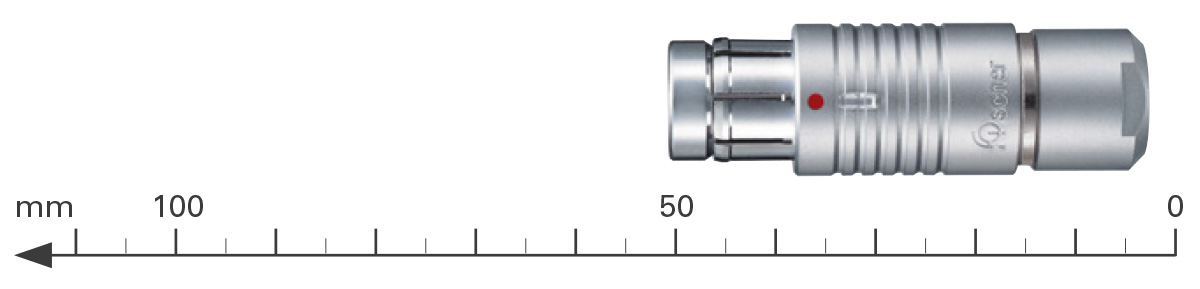

Fischer Core Series AluLite™

ULTRA-LIGHT | RUGGED | HIGHLY CONFIGURABLE

- Lightweight, 50% lighter than brass equivalent

- Chromium-plated aluminum for best chemical resistance

- Up to IP68 sealing (liquid tight)

- Hermetic versions available (gas tight, vacuum tight)

- 360° EMC shielding

- Colors available for visual coding

- 10,000 mating cycles

- Lightweight, 50% lighter than brass equivalent

- Chromium-plated aluminum for best chemical resistance

- Up to IP68 sealing (liquid tight)

- Hermetic versions available (gas tight, vacuum tight)

- 360° EMC shielding

- Colors available for visual coding

- 10,000 mating cycles

Significantly lighter (around 50%) than typical metal connectors, the Fischer Core Series AluLite™ is ideal for mobile equipment, portable systems or hand-held devices. This push-pull circular connector smoothly fits in with your product design and offers an easy-to-use color coding system with products available in several colors.

| Parameter | Value | Standard |

| Mating cycles | 10,000 |

IEC 60512-9-1

EIA-364-09 |

|

Temperature range – Viton O-ring at plug interface – EPDM O-ring (Low temp) at plug interface |

-20°C to +200°C -50°C to +160°C |

IEC 60068-2-14 |

| Sealing | IP68 ; 2m submersion for 24 hours | IEC 60529 |

|

Hermeticity – DEE, DBPE, DBPLE |

Hermetic: Tested: <10-8 mbar l/sec. IP69 |

IEC 60068-2-17 test Qk method 3, alternative b IEC 60529 |

| Vibration | Contact interruption < 1μs (10-2000Hz /15G) | MIL-STD-202 Method 204, Condition B |

| Parameter | Series | ||||

| 102 | 103 | 1031 | 104 | 105 | |

|

Grounding resistance1) (shell-to-shell) |

Typical 50 mΩ | ||||

| EMC shielding | 360-degree EMC shielding | ||||

1) IEC 60512-2-6-2f

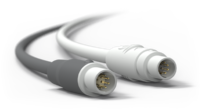

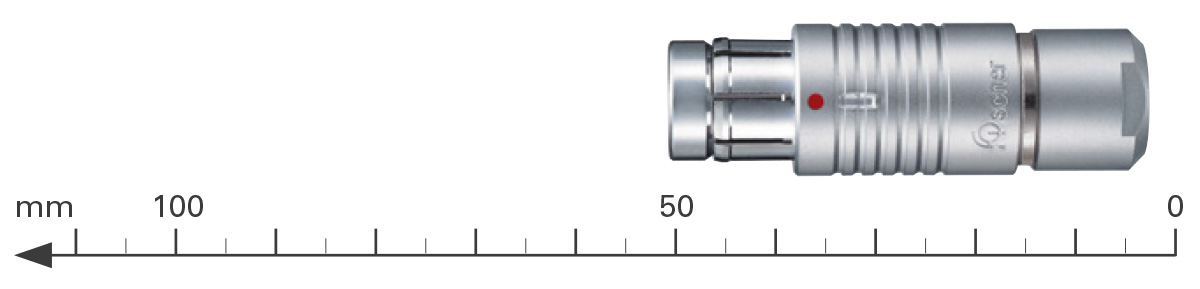

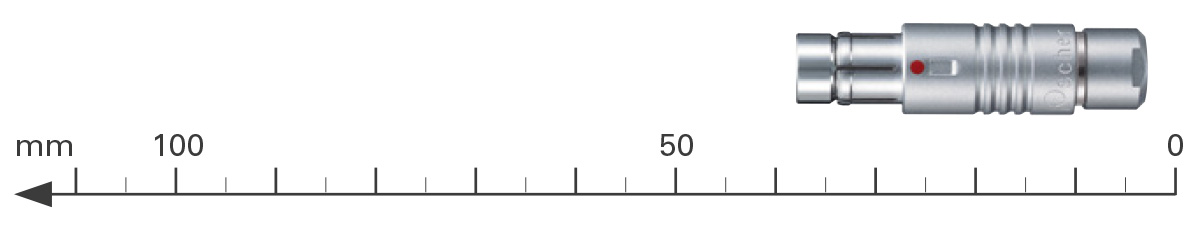

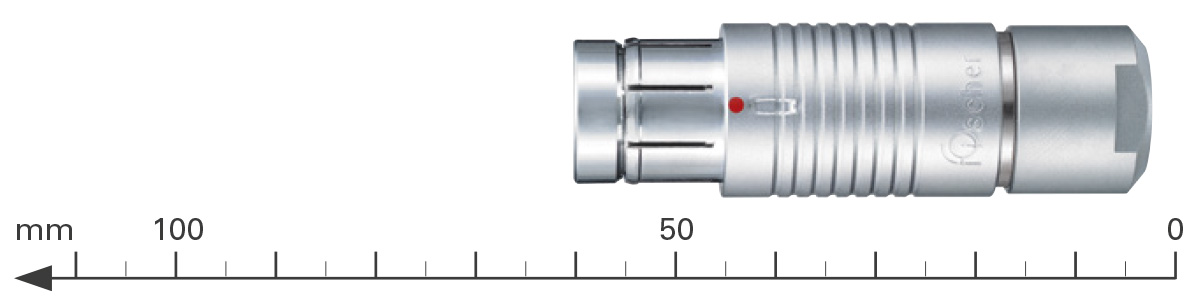

Fischer Core Series Plastic

EASY TO USE | DURABLE | LIGHTWEIGHT

- High performing plastic materials

- Sterilizable and chemical resistant (autoclave, Cidex, EtO, gamma radiation, Steris® or Sterrad®)

- Up to IP68 sealing mated (liquid tight)

- Resistant to large temperature variations

- High density of contacts

- EMI/RFI shielding for reliable data transmission

- Color coding for easy operations

- 5,000 mating cycles

- High performing plastic materials

- Sterilizable and chemical resistant (autoclave, Cidex, EtO, gamma radiation, Steris® or Sterrad®)

- Up to IP68 sealing mated (liquid tight)

- Resistant to large temperature variations

- High density of contacts

- EMI/RFI shielding for reliable data transmission

- Color coding for easy operations

- 5,000 mating cycles

Specially designed to ensure maximum user safety and electric shock protection, the Fischer Core Series Plastic features fully insulated plastic connector bodies. The plug and receptacle can be color-coded to enable easy identification and prevent incorrect mating. Convenient to use, the SureGrip plug body can be securely and easily gripped with gloves. Resistant to up to 5,000 mating cycles and completely sterilizable, this series is ideal for industrial and FDA-approved medical devices.

| Characteristic | Product type | Value | |

| Sealing performance | Plug (SI or SI 405) |

– with sealed cable clamp and cap |

IP67 |

| IP50 | |||

| Receptacle (DBP 405) | IP50 | ||

| 5,000 mating cycles | |||

| Characteristic | Product type | Value | |

| Sealing performance | Plug (SI 4032) |

– with sealed cable clamp

– with cap or mated with sealed receptacle (DBPO 4032) |

IP68 |

| IP50 | |||

| Sealed receptacle (DBPO 4032) | Mated with sealed plug or with cap | IP68 | |

| Unsealed receptacle (DBP 4032) | IP50 | ||

| Endurance | 5,000 mating cycles | ||

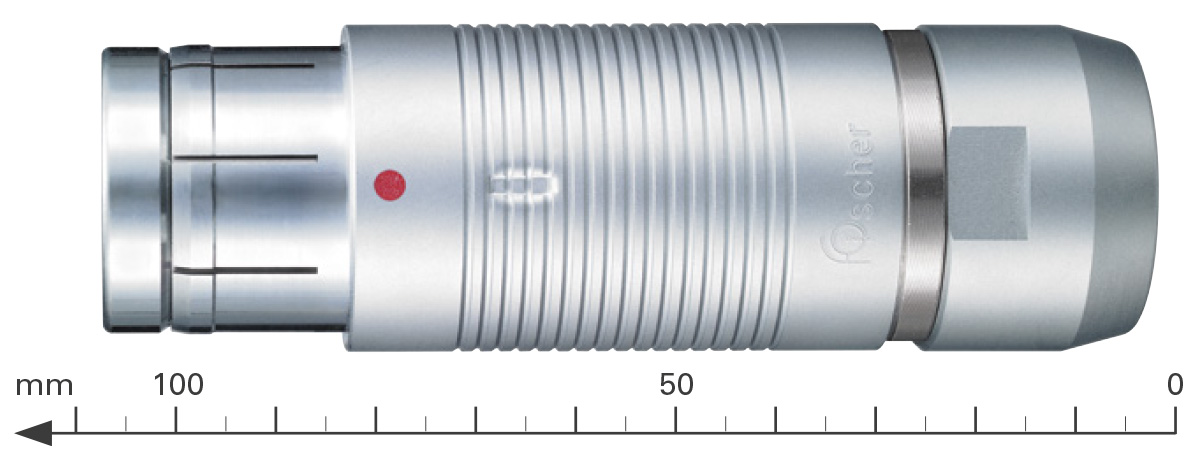

Fischer Core Series Disposable

COST-EFFECTIVE | EASY TO USE | MODULAR

- Cost-effective single use plugs

- Sterilizable (EtO, Gamma)

- Lightweight and shock resistant

- Reliable and faultless handling

- Easy and fast assembly (snap-lock design)

- Modular or turnkey solution

- Color-coded for easy identification

- Cost-effective single use plugs

- Sterilizable (EtO, Gamma)

- Lightweight and shock resistant

- Reliable and faultless handling

- Easy and fast assembly (snap-lock design)

- Modular or turnkey solution

- Color-coded for easy identification

The Fischer Core Series Disposable meets the needs of medical device manufacturers whose products are designed for disposal after a short number of uses. This push-pull circular connector is a cost-effective solution that does not compromise on quality. Whether directly mounted into a disposable hand piece, overmolded or mounted onto a disposable cable, this plastic connector offers multiple configurations and optimally suits a wide array of applications, from catheters to surgical hand tools and more. This turnkey solution is pre-cabled, and thus fast and simple to integrate into any medical device. With an ingress protection of IP40 and a high degree of electrical insulation, it is compatible with Fischer Core Series Brass 104 receptacles.

|

Sealing rating

– Single shell

– Two-piece shell |

IP30

IP40 |

| Operating temperature range | -20°C to +65°C |

| Endurance | 10 mating cycles |

| Gamma irradiation for sterilization | Tested to withstand irradiation up to 60 kGy per ISO 11137-2 |

| EtO for sterilization | Tested with a standard EtO sterilization cycle per ISO 11135 |

| Mating / Unmating force | Typ. 10-20 N |

Fischer Core Series Broadcast

THE BEST OF TRIAX | RUGGED | FOR OUTDOOR USE

- Standard for TRIAX broadcast cameras

- HD/SD signal compliant, constant quality of transmission

- Long transmission distance (30% longer than Triax 14)

- 360° EMC shielded

- Corrosion resistant

- Up to IP68 sealing mated (liquid tight)

- Operating temperatures from -55 °C to +135 °C

- 5,000 mating cycles

- Standard for TRIAX broadcast cameras

- HD/SD signal compliant, constant quality of transmission

- Long transmission distance (30% longer than Triax 14)

- 360° EMC shielded

- Corrosion resistant

- Up to IP68 sealing mated (liquid tight)

- Operating temperatures from -55 °C to +135 °C

- 5,000 mating cycles

Professional broadcasters and producers demand high-performance and reliable equipment. The Fischer 1051 Triax HD Pro+™ connectors link HD video cameras and related equipment dependably. Plug-and-play solutions include fiber optic signal, triaxial and power connectors, plus options for connecting the camera control unit (CCU) to cameras, equipping outside broadcasting (OB) vans and connecting fiber media converters.

Tools & accessories

Fischer Connectors offers a selection of accessories designed to extend the applications and improve the protection of our solutions. Choose from a variety of connector and cable accessories that improve ease of use and performance, and enable installation, maintenance and quick repairs.